Restoring marble and applying NeverEtch is an artisanal process that combines training, skill, attention to detail and the proper tools. Prior to beginning any project, the surfaces are evaluated to determine surface condition, appearance, and the necessary corrective measures.

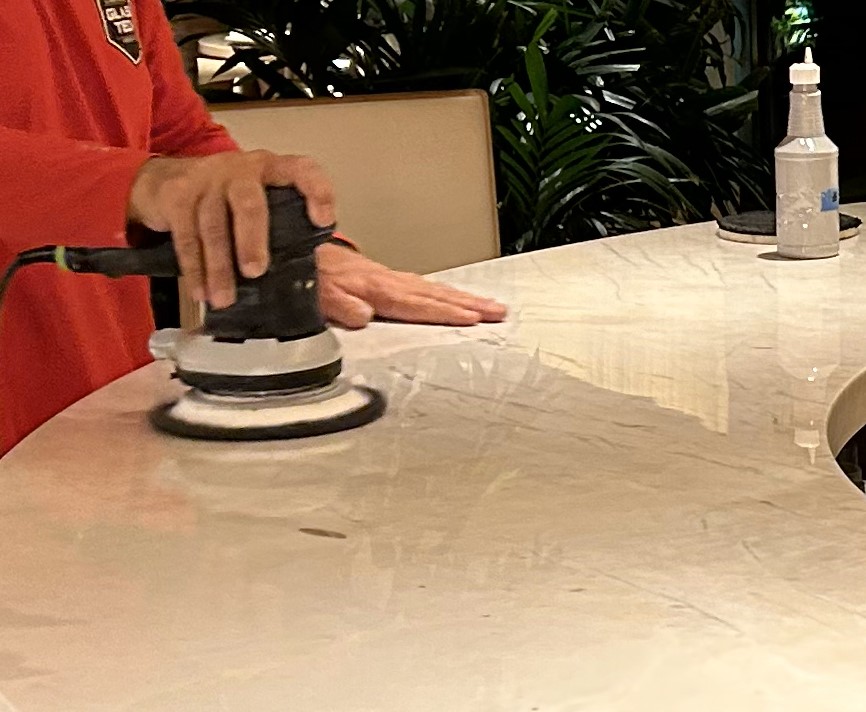

Technicians use FESTOOL tools and equipment utilizing HEPA filtration to ensure a dust-free environment. NeverEtch coating has low VOC’s and is free of any strong solvents or offensive chemicals. Surrounding surfaces including flooring are protected during the entire process.

SURFACE RESTORATION & PREP.

The restoration and corrective process begins by

removing etching, staining, contaminants, and imperfections. This important step creates the

proper base for coating application.

After restoration is completed, all surfaces are cleaned and prepped for the

NeverEtch coating application.

APPLYING NEVERETCH

NeverEtch is evenly distributed and worked into the surface. After sufficient working time, the coating is allowed to flow out self-level.

CURING LAMP IN ACTION

Next, NeverEtch is cured using high intensity UV lamps. The curing process is what creates the hard surface making it impervious to etching and staining.

SANDING AND POLISHING PROCESS

Depending on the desired finish, coated surfaces are

sanded and polished to the desired appearance.

NeverEtch can be sanded to a natural honed finish and polished to a glass-like

brilliance.

After achieving the desired finish, coated surfaces are given a

final cleaning and tested for stain and etch

resistance. Surfaces are now ready for use and will not be affected by acidic

liquids, beverages, food, or other products that would normally harm the appearance of marble.

Care is simple and minimal.